The Evolution of Plastic Concrete Forms

A Journey Through Innovation and Application

The construction industry has seen numerous advancements over the past few decades, and one of the significant innovations is the use of plastic concrete forms. Introduced over 35 years ago, these forms have revolutionized concrete construction, offering various benefits that traditional wood or metal forms could not provide. In this document, we will explore the history, advantages, applications, and the future potential of plastic concrete forms.

History and Development

Plastic concrete forms first began to gain traction in the early 1980s. The development was driven by the need for more durable, reusable, and cost-effective alternatives to traditional concrete forms. The initial forms were made from high-density polyethylene (HDPE) and polypropylene, materials known for their strength, flexibility, and resistance to the harsh conditions of concrete curing.

Advantages of Plastic Concrete Forms

Plastic concrete forms offer a myriad of benefits that have contributed to their widespread adoption in the construction industry:

- Durability: Unlike wood, plastic forms do not rot, warp, or succumb to insect damage. They can withstand the rigors of concrete placement and curing without deteriorating.

- Reusability: Plastic forms can be reused multiple times, significantly reducing waste and the cost of formwork over time.

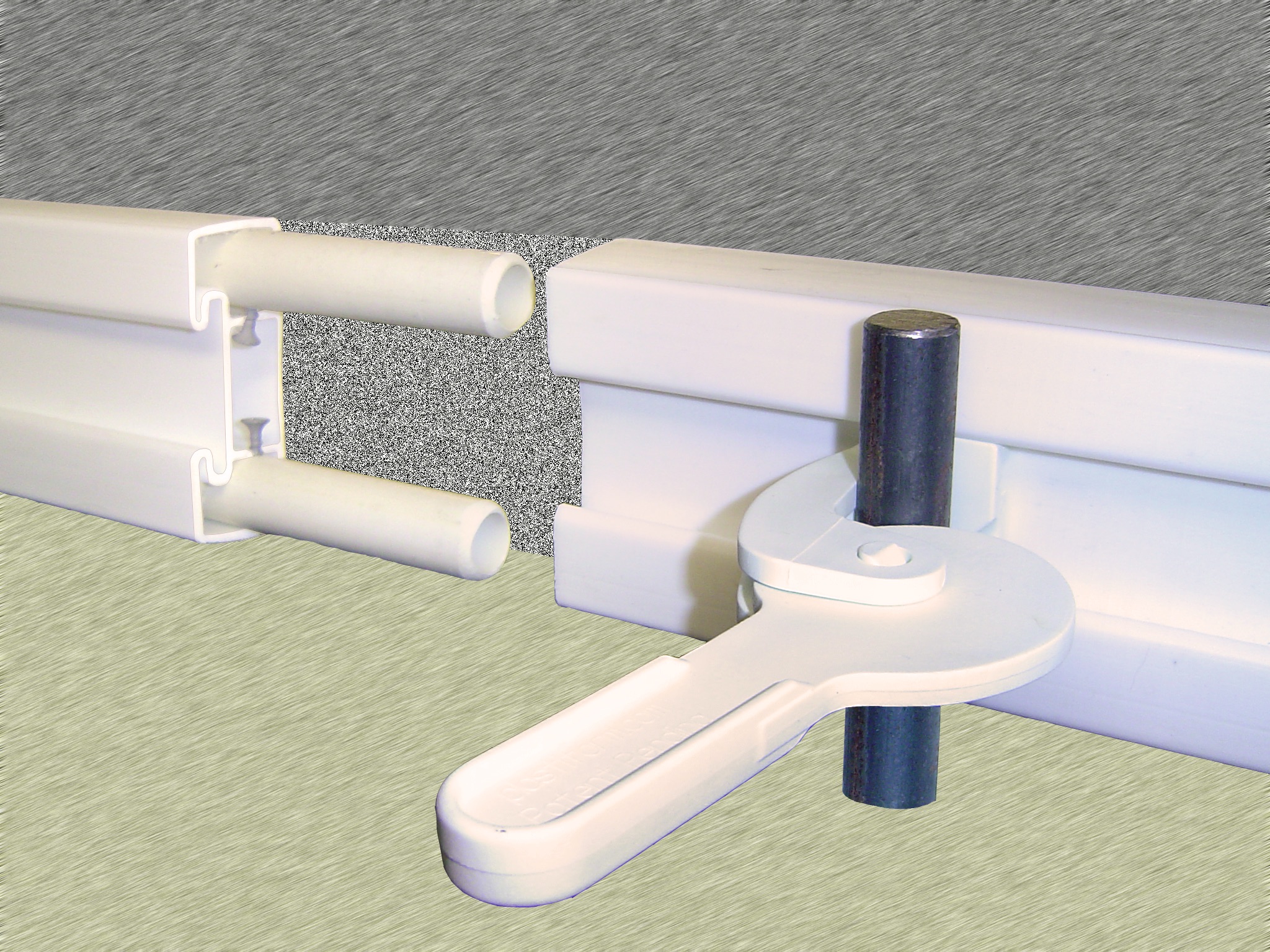

- Lightweight: These forms are lighter than metal, making them easier to handle, transport, and install, which can reduce labor costs and improve site efficiency.

- Ease of Cleaning: The non-stick surface of plastic forms makes them easier to clean and maintain, ensuring a smooth finish on the concrete.

- Versatility: Plastic forms can be molded into various shapes and sizes, accommodating complex architectural designs and structural needs.

- Environmental Impact: The reusability and recyclability of plastic forms contribute to more sustainable construction practices.

Applications in Construction

Plastic concrete forms have been utilized in various construction projects, from residential buildings to large-scale infrastructure. Some of the notable applications include:

- Foundations: Plastic forms are used for pouring concrete foundations, ensuring a robust base for buildings.

- Walls and Columns: The flexibility of plastic forms allows for the creation of intricate wall and column designs, enhancing the aesthetic appeal of structures.

- Roads and Bridges: In infrastructure projects, plastic forms provide the durability required for long-lasting roads and bridges.

- Precast Concrete: Plastic forms are often used in the precast concrete industry, where components are manufactured off-site and assembled on-site. This method benefits from the precision and consistency of plastic forms.

Case Studies and Innovations

Over the years, various case studies have demonstrated the effectiveness of plastic concrete forms in diverse projects. For instance, a major highway bridge construction utilized plastic forms to expedite the project timeline and reduce costs. Innovations in plastic form technology, such as the incorporation of reinforced fibers, have further enhanced their strength and durability.

The Future of Plastic Concrete Forms

The future of plastic concrete forms looks promising, with ongoing advancements aimed at enhancing their performance and sustainability. Innovations such as biodegradable plastics and smart forms embedded with sensors for real-time monitoring are on the horizon. As the construction industry continues to prioritize sustainability and efficiency, plastic concrete forms are expected to play a crucial role in shaping the future of concrete construction.

In conclusion, plastic concrete forms have transformed the construction landscape over the past 35 years. Their durability, reusability, and versatility have made them an invaluable asset in various construction projects. As technology advances and new materials emerge, plastic concrete forms will continue to evolve, offering even greater benefits to the industry and contributing to more sustainable building practices.